Hore nalikhalase tse rovings or likhoele tse khutšoane tsa khalase, khalase ea fiberglass or precio fibra de carbonoli eketsoa ho matrix a thermoplastic, sepheo ke ho ntlafatsa thepa ea mochini le sebopeho sa polymer.Ho na le liphapang tse ngata pakeng tsa mekhoa e 'meli e meholo ea ho matlafatsa thermoplastics bakeng sa ho bōptjoa ha ente, ho tloha kamoo li kopantsoeng kateng le matrix a polymer, ho ea boemong ba ts'ebetso eo ba ka fanang ka eona,' me mofuta o le mong oa fiber o ka ba o eketsehileng E 'ngoe e loketse haholoanyane, empa bakeng sa shaper, phapang e khōlō pakeng tsa likhoele tse khutšoanyane le tse telele ke tekanyo eo li sebetsoang ka eona.

Ho sebetsana le fiber e telele e matlafalitsoeng ke thermoplastics

Sepheo sa mantlha sa ho sebetsana le thermoplastics e matlafalitsoeng ka fiber e telele ke ho boloka bolelele ba fiber, bo bohlokoa bakeng sa ho matlafatsa matla le ho tiea.Ho robeha ha fiber ho ka ba le phello e mpe ho thepa ea motsoako oa polymer mme qetellong ho ka senya melemo ea ho sebelisa likhoele tsa fiber ea khalase.Ho sebetsa ka mokhoa o sa nepahalang le lisebelisoa tse fosahetseng le moralo oa likarolo, kapa ts'ebeliso ea lisebelisoa tse sa sebetseng kapa li-setups, li ka lebisa ho robeheng ha fiber.

Ho fapana le lipolasetiki tse matlafalitsoeng tse entsoeng ka fiber, lisebelisoa tse matlafalitsoeng tsa fiber e telele hangata li entsoe ka pultrusion.Mokhoa ona o kenyelletsa ho otlollakgalases rovinge kenngoe ka resin ea thermoplastic ka ho kenngoa ho khethehileng (e le hore resin e khone ho pota-pota le ho kopanya likhoele), ebe e khaola likhoele tse fetisitsoeng hore e be li-pellets, likhoele tse ka har'a li-pellets hangata li 12mm. , 'me bolelele bona ke ba bohlokoa bakeng sa ho nolofalletsa polymer ho fetisetsa khatello ea kelello ho likhoele tse matla.

Ha li-pellets tsena li sebelisoa bakeng sa ho etsa ente, likhoele tse telele lia hokahanngoa 'me li entsoe ka thata ho etsa masapo a ka hare a fanang ka matla le ho tiea.Ha ho bapisoa le lisebelisoa tse tlatsitsoeng ka fiber e khuts'oane, li-composites tse matlafalitsoeng ka likhoele tse telele, hore nalikhoele tsa fiberglasskapa likhoele tsa k'habone, li fana ka litekanyo tse phahameng ho isa ho boima ba 'mele, boima ba tšusumetso, bophelo bo bolelele ba mokhathala oa cyclic, le ho hanyetsa mocheso o pharaletseng le botsitso bo betere ba sebopeho.

Lisebelisoa tsena tse tšoarellang li fana ka ts'ebetso ea sebopeho se tšoanang le tšepe, leha ho le joalo li bobebe ho feta tšepe, 'me li khona ho nka monyetla ka melemo ea ts'ebetso ea ho bopa ente.1k lesela la carbon fibere bohlokoa ka ho khetheha e le sebaka sa tšepe hobane e bobebe ho feta tšepe ka 70% ebile e bobebe ho feta tšepe.Aluminium e bobebe ka 40%, kahoo likhomphutha tse matlafalitsoeng ka nako e telele li ka sebelisoa ho etsa likarolo tse hlokahalang tsa likoloi, thepa ea lipapali, sebaka sa sefofane, thepa ea bareki le lisebelisoa tsa indasteri.Li-resin tse tloaelehileng tsa motheo li kenyelletsa polyamide (PA kapa nylon), polypropylene (PP), rigid thermoplastic polyurethane (ETPU), le li-resin tse phahameng tsa mocheso tse kang polyetheretherketone (PEEK), polyphthalamide (PPA), le polyamide.Ether imide (PEI) joalo-joalo Le hoja thermoplastic leha e le efe e ka matlafatsoa ka likhoele, ke tse ling feela tse fanang ka ts'ebetso e phahameng hobane li matlafatsoa hamolemo.Ha e le hantle, li-resin tsa semi-crystalline li matlafatsoa hamolemo ke likhoele ho feta li-amorphous resin, ho bolelang hore ho satalla ha bona le matla a tsona li eketseha le ho feta.

Lintlha tsa Ts'ebetso ea Lisebelisuoa tse Matlafalitsoeng tsa Fiber e telele

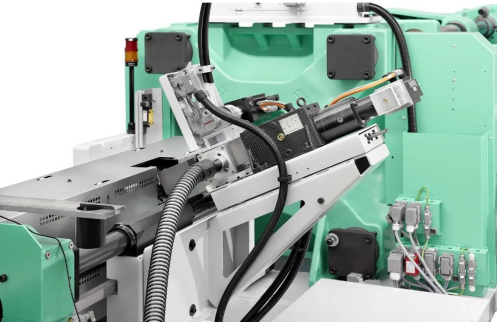

Ha ho bapisoa le li-resin tse sa fetoloang kapa tse nang le granular tse tlatsitsoeng ka phofo, ho bopa li-composites tse matlafalitsoeng ka fiber e telele ho na le litlhoko tse itseng holim'a hlobo, liheke, lisebelisoa tsa ho bopa le karolo ea moralo.Mekhoa e sebelisoang ho sebetsana le lisebelisoa tsena le eona e fapane le ea li-polymers tse matlafalitsoeng ka fiber e khutšoanyane.

Joalokaha ho boletsoe pejana, ho boloka bolelele ba fiber ke senotlolo sa katleho.Lintlha tse ka bakang ho khutsufatsoa ha fiber li kenyelletsa khatello e phahameng le ho kuta ho tsoa ho screw ea ente, joalo ka likhutlo tse bohale tsa hlobo le sistimi ea semathi.Ho boloka bolelele ba fiber, ho na le lintlha tse 3 tsa bohlokoa tsa ts'ebetso tseo u lokelang ho li ela hloko:

1. Lintho tse entsoeng ka hlobo le moralo

Le hoja likhoele tse telele li apara hanyenyane holim'a hlobo ho feta likhoele tse khutšoanyane hobane ho na le lipheletso tse fokolang tse kang tsa nale tse amang hlobo, mofuta o tšoanang oa tšepe ea hlobo o loketse li-polymers tse matlafalitsoeng ka nako e telele le tse khutšoanyane, tse tloaelehileng ka ho fetisisa. ke tšepe ea hlobo ea P20, e ka mamellang liente tse fetang 100,000 kamehla.Haeba ho hlokahala hore ho tšoarelle nako e telele (kaholimo ho liente tse 100,000), tšepe ea H13 chrome molybdenum kapa tšepe e thata ea moea ea A9 ke khetho e ntle.Ka kakaretso, hlobo e thata ke khetho e ntle ka ho fetisisa bakeng sa ho sebetsana le thermoplastics e matlafalitsoeng ka fiber.Bakeng sa hlobo e tsofetseng, li ka nchafatsoa ho sebelisoa theknoloji ea electroplating.Mefuta ea aluminium e ka sebelisoa le haeba ho tlameha ho hlahisoa li-prototype ho netefatsa moralo.

2. Ho etsa thepa

Thermoplastics e matlafalitsoeng ka fiber e telele e ka sebetsoa ka lisebelisoa tse tloaelehileng tsa ente tse nang le liphetoho tse 'maloa feela tse sa feleng ho boloka bolelele ba fiber le ho amohela li-viscosity tse phahameng.Sekurufu sa khatello e tlase kapa sepheo se akaretsang se nang le selikalikoe se sa khutleng se lumellang ho phalla ka bolokolohi holimo ho khothaletsoa.Li-nozzles tsa morero-kakaretso li ka sebelisoa, empa li-nozzles tsa nayilone li lokela ho qojoa hobane sebopeho sa tsona sa hourglass (se etselitsoeng ho thibela ho rotha) se thibela ho phalla, ho etsa hore ho kuta, 'me ho baka ho senyeha ha fiber.Keletso e 'ngoe ea ho fokotsa ho kuta ke ho qoba meralo e sothehileng ea nozzle.Ka kakaretso, masoba a maholo a nozzle (bonyane 5.6 mm) a thusa ho feta ha li-resin tse matlafalitsoeng ka viscous.

Molao o motle bakeng sa mochini ofe kapa ofe oa ente ke ho kenya 60-70% feela ea molumo.Ho thunya ho hoholo ho eketsa nako ea ho seta bocha, ha boholo bo fokolang haholo bo bolela hore thepa e lula ka har'a moqomo nako e telele, e leng se ka lebisang ho theoheng.

3. Maemo a ho sebetsa

Mabapi le ts'ebetso, ho bohlokoa ho sebetsana le lintlha tse peli: warpage le creep.Ka kakaretso, likarolo tsa thermoplastic tse matlafalitsoeng ka fiber e telele li na le mathata a fokolang ho fetakhalase ea fiberglass e khuts'oanelikarolo hobane matsoelintsoeke a filament fokotsa shrinkage differential, empa ente bōptjoa likarolo tse telele tsa faeba ntse deform, lebaka le leng ke hore likhoele phallang hammoho Orientation lolamisiwa, ha e ntse e matlafatsa karolo matla, ka lebisa ho anisotropy.Ho thibela ho loana, libaka tse ling tsa liheke kapa liqapi tsa likarolo li ka sebelisoa ho qoba ho lumellana ho feteletseng ha fiber libakeng tse sa hlokeng matla a phahameng ho mamella meroalo ea moralo.

Boloka molemo oa likhoele tse telele

Katleho ea ho bopa ha li-composites tse matlafalitsoeng ka fiber e telele e hloka phetoho e itseng ea litataiso tsa moralo le methati ea ts'ebetso e sebetsang ho resin e sa matlafalitsoeng le metsoako e khuts'oane ea fiber.Ho fumana molemo ka ho fetisisa ho li-fibers tse telele (tse bitsang chelete e ngata ho feta thepa e sa tlatsoang kapafiberglass chopped likhoele reinforcementka lebaka la ts'ebetso ea bona e phahameng), mekhoa e metle e tlameha ho lateloa ts'ebetsong eohle.Haeba likhoele tse telele li robehile kapa li sa tsamaisane hantle ka lebaka la ho ts'oaroa ka mokhoa o fosahetseng, moralo oa "die" kapa ho seta lisebelisoa, matla a bona a phahameng le melemo ea bona e phahameng e tla fokotseha kapa e lahlehe.

#likhalase tse rovings#likhoele tse khutšoane tsa khalase#1k lesela la carbon fiber#khalase ea fiberglass e khuts'oane#fiberglass chopped likhoele reinforcement

Nako ea poso: Oct-21-2022