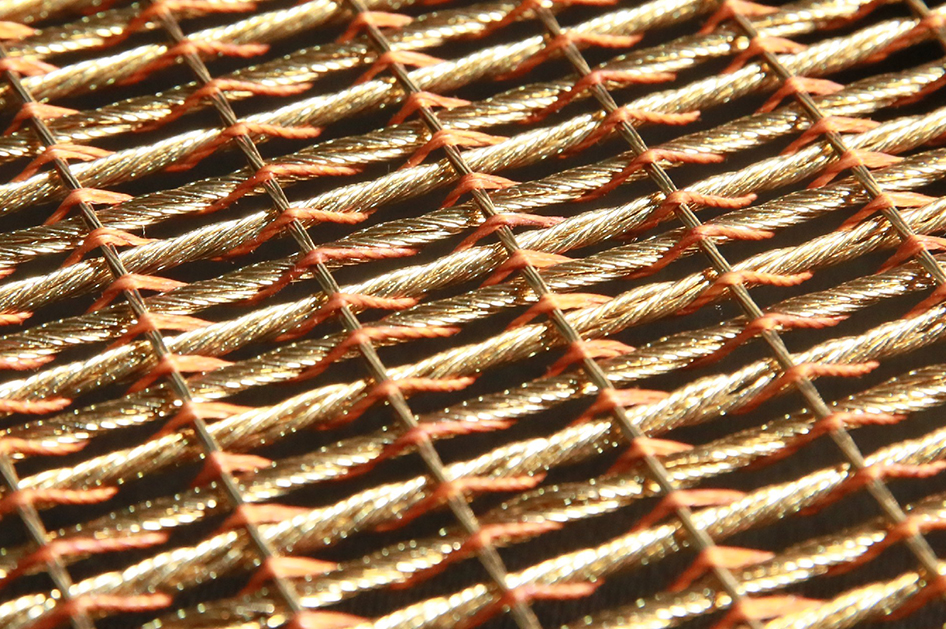

Spiral-Shaped Mesh e ka etsoa ka mokhoa o ikhethileng ka theko e tlase 80 100 200 mesh

Kenyelletso ea Sehlahisoa

Ka ho sebelisa sehlahisoa sena e le lisebelisoa tsa marapo a lebanta le tsamaisang rabara le ho sebelisa mokhoa o khethehileng o thibelang malakabe e le sekhomaretsi se koahelang, lebanta la conveyor le ka tsamaisa thepa ea mocheso o phahameng pakeng tsa 200 ° C le 800 ° C.

Likarolo tsa Sehlahisoa

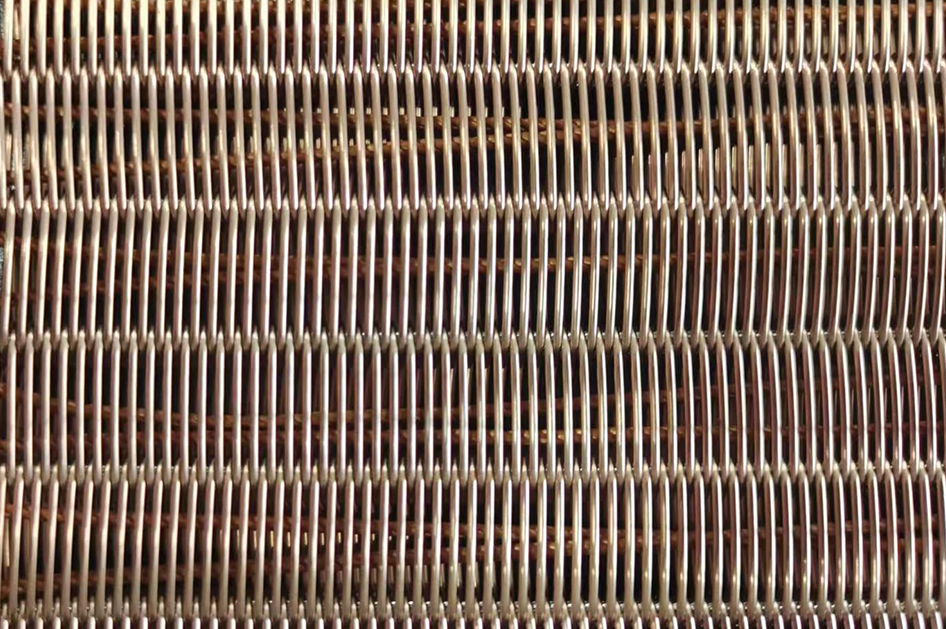

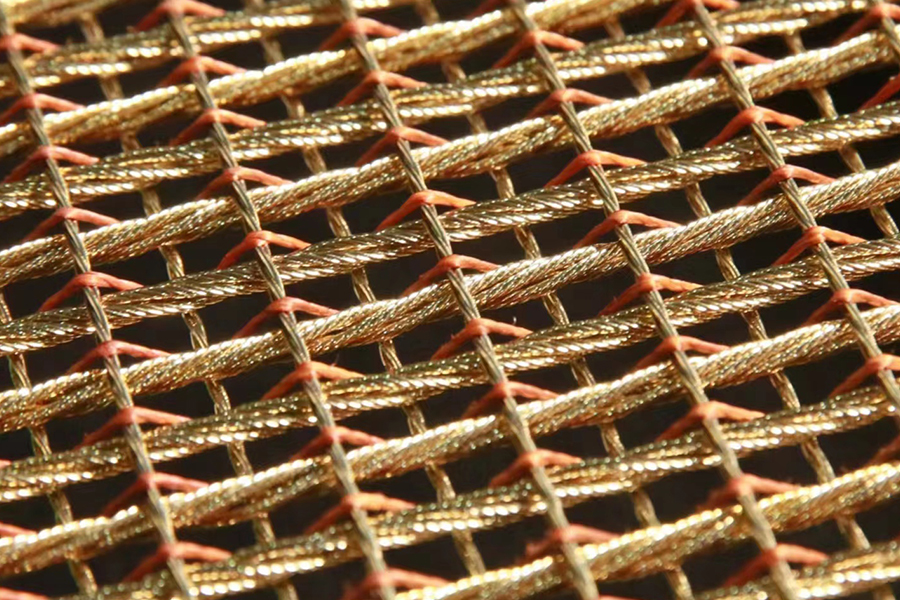

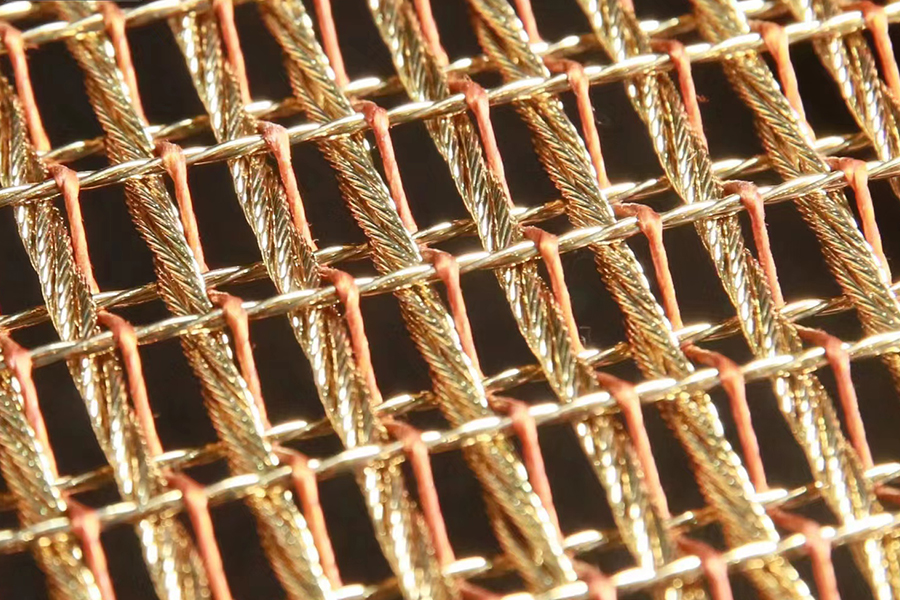

Mokotla oa lebanta ke tšepe ea tšepe ea spiral mesh ea bohlokoa ea lebanta, e nang le litšobotsi tsa ho hanyetsa mollo, ho hanyetsa mocheso o phahameng, ho hanyetsa ho phunya, ho hanyetsa meokho, ho thibela lelakabe, matla a phahameng a tsitsitseng, bolelele bo bonyenyane, sebopeho se setle sa groove, le matla a maholo a kopantsoeng ( Sebetsa ka kopanelo 100%), lihokelo tse bonolo, ts'ebetso e bonolo le likarolo tse ling.

Lisebelisoa tsa Sehlahisoa

E rarolla mathata a core layer delamination, blistering, ho koahela sekhomaretsi se oelang, ho robeha ka kakaretso le bolelele, le ho khaoha ho kopaneng hoo mabanta a tloaelehileng a conveyor a ke keng a hlola a a sebelisa.Bophelo ba tšebeletso ea mabanta a conveyor a tšepe a tšepe a ka fihla makhetlo a 3-5 ho feta a mabanta a tloaelehileng a mocheso o phahameng a hanyetsanang le mocheso.